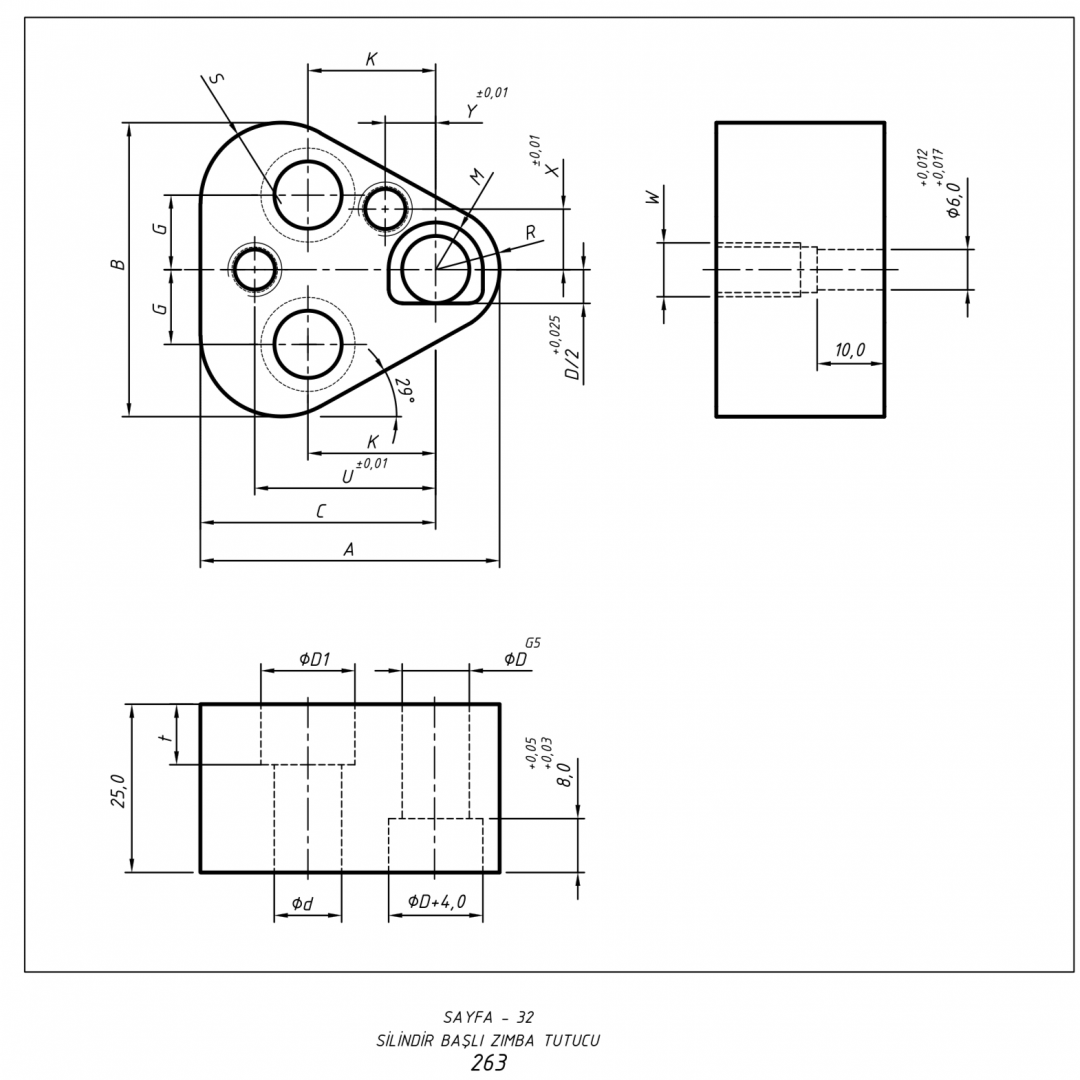

Punch Retainers

| MATERIAL | HARDNESS |

|---|---|

| Production Steel | 48-50 HRC |

| 263. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | A | B | C | G | K | M | R | S | U | X | Y | D1 | d | t | W |

| 10 | 44,5 | 43,7 | 35,0 | 11,1 | 19,0 | 7,75 | 9,5 | 12,0 | 26,925 | 9,0 | 7,5 | 14,0 | 9,0 | 9,5 | M8x35 |

| 13 | 50,8 | 50,0 | 38,1 | 14,3 | 19,0 | 9,25 | 12,7 | 15,2 | 29,970 | 12,0 | 6,5 | 15,0 | 9,0 | 9,5 | M8x35 |

| 16 | 54,0 | 53,2 | 39,7 | 15,9 | 19,0 | 10,75 | 14,3 | 16,8 | 31,750 | 13,5 | 6,3 | 15,0 | 9,0 | 9,5 | 10x40 |

| 20 | 60,3 | 59,5 | 42,8 | 17,5 | 19,0 | 12,75 | 17,5 | 20,0 | 33,530 | 16,5 | 5,0 | 18,0 | 11,0 | 11,5 | 10x40 |

| 25 | 69,9 | 69,1 | 47,7 | 19,8 | 23,8 | 15,25 | 22,2 | 24,7 | 40,640 | 22,0 | 7,0 | 20,0 | 13,5 | 13,5 | M12x40 |

| 32 | 69,9 | 69,1 | 47,7 | 19,8 | 23,8 | 18,75 | 22,2 | 24,7 | 40,640 | 22,0 | 7,0 | 20,0 | 13,5 | 13,5 | M12x40 |

| ORDER EXAMPLE | |

|---|---|

| Diameter(d) | 16 |

| Order Code | 263.16 |

Punches Technical Specifications

Kalıpyansan punches are manufactured to perform hole punching in all punching and cutting dies in accordance with DIN / ISO standards or requested specifications in different forms and materials in colored metals (brass, copper, aluminum, etc.) soft, hard and chrome nickel (stainless) sheets. Offering high performance and long die life, Kalıpyansan punches minimize the need to change tools in the mold shop and significantly reduce costs. Matrices are recommended wherever Kalıpyansan punches are used. They are manufactured to perform punching operations at high performance in all punching and cutting dies in compliance with DIN / ISO standards or as per requested specifications.

Ejector Pins Technical Specifications

Kalıpyansan ejector pins make a difference in plastic and metal injection molds with their hardened and very precisely ground bodies.