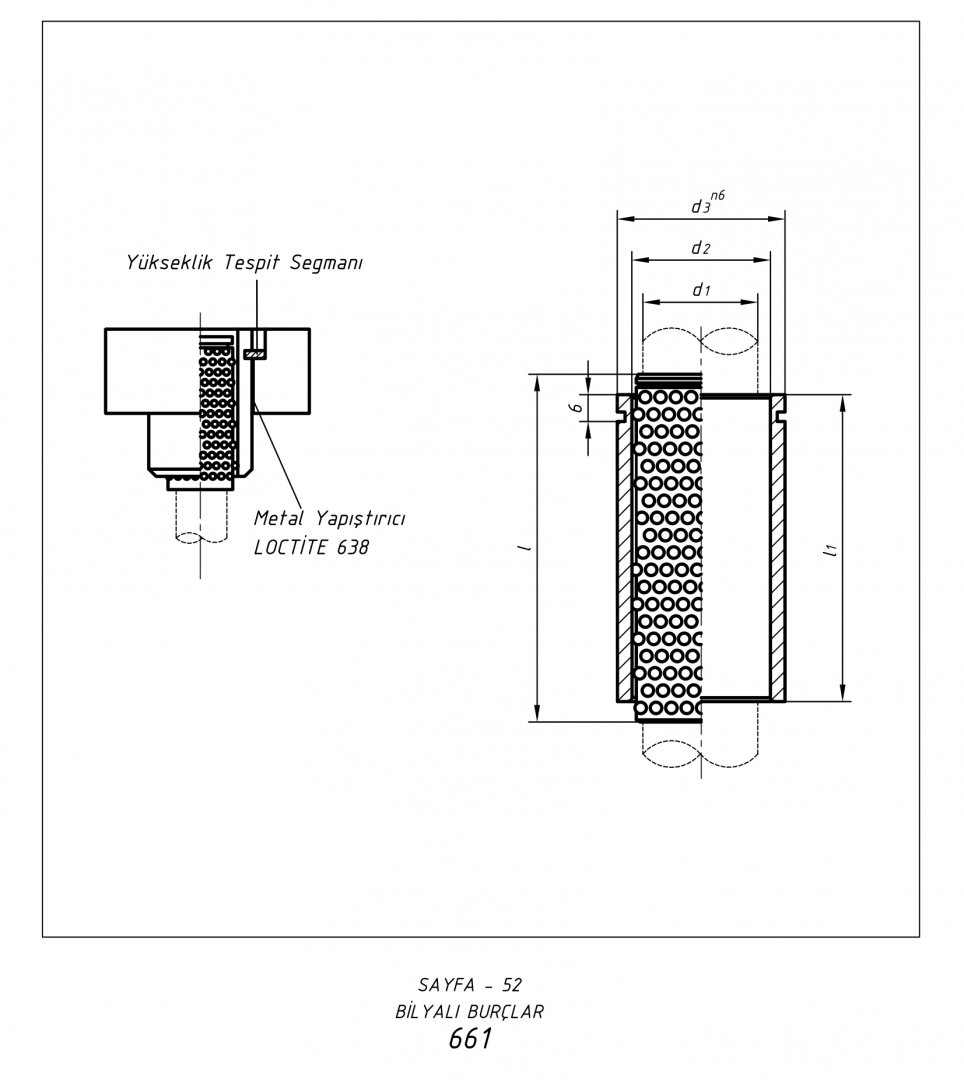

Ball Bearing Guide Bushes

| MATERIAL / BUSH | HARDNESS | DEPTH | BALL CAGE | BALL |

|---|---|---|---|---|

| Tool Steel | 60 ± 2 HRC | 0,5 mm | Brass MS 58 | Hardened Steel DIN 5401 |

| d1 | l1 | l | d2 | d3 | Order Code |

|---|---|---|---|---|---|

| 12 | 35 | 40 | 17 | 22 | 661.12.035 |

| 15 | 40 | 50 | 21 | 30 | 661.15.040 |

| 15 | 50 | 55 | 661.15.055 | ||

| 16 | 40 | 50 | 22 | 661.16.040 | |

| 16 | 55 | 60 | 661.16.055 | ||

| 18 | 35 | 40 | 24 | 36 | 661.18.035 |

| 18 | 50 | 55 | 661.18.050 | ||

| 18 | 65 | 70 | 661.18.065 | ||

| 18 | 75 | 80 | 661.18.075 | ||

| 19 | 35 | 40 | 25 | 661.19.035 | |

| 19 | 50 | 55 | 661.19.050 | ||

| 19 | 65 | 70 | 661.19.065 | ||

| 19 | 75 | 80 | 661.19.075 | ||

| 20 | 35 | 40 | 26 | 661.20.035 | |

| 20 | 50 | 55 | 661.20.050 | ||

| 20 | 65 | 70 | 661.20.065 | ||

| 20 | 75 | 80 | 661.20.075 | ||

| 24 | 40 | 50 | 30 | 40 | 661.24.040 |

| 24 | 55 | 60 | 661.24.055 | ||

| 24 | 70 | 80 | 661.24.070 | ||

| 24 | 85 | 90 | 661.24.085 | ||

| 25 | 40 | 50 | 31 | 661.25.040 | |

| 25 | 55 | 65 | 661.25.055 | ||

| 25 | 70 | 80 | 661.25.070 | ||

| 25 | 85 | 90 | 661.25.085 |

| d1 | l1 | l | d2 | d3 | Order Code |

|---|---|---|---|---|---|

| 30 | 45 | 55 | 38 | 48 | 661.30.045 |

| 30 | 60 | 70 | 661.30.060 | ||

| 30 | 80 | 85 | 661.30.080 | ||

| 30 | 100 | 105 | 661.30.100 | ||

| 32 | 45 | 55 | 40 | 661.32.045 | |

| 32 | 60 | 70 | 661.32.060 | ||

| 32 | 80 | 85 | 661.32.080 | ||

| 32 | 100 | 105 | 661.32.100 | ||

| 38 | 50 | 55 | 48 | 58 | 661.38.050 |

| 38 | 65 | 75 | 661.38.065 | ||

| 38 | 90 | 95 | 661.38.090 | ||

| 38 | 110 | 115 | 661.38.110 | ||

| 40 | 50 | 55 | 661.40.050 | ||

| 40 | 65 | 70 | 661.40.065 | ||

| 40 | 90 | 95 | 661.40.095 | ||

| 40 | 110 | 115 | 661.40.110 | ||

| 48 | 55 | 60 | 58 | 68 | 661.48.055 |

| 48 | 75 | 80 | 661.48.075 | ||

| 48 | 95 | 100 | 661.48.095 | ||

| 48 | 120 | 140 | 661.48.120 | ||

| 50 | 55 | 60 | 60 | 661.50.055 | |

| 50 | 75 | 80 | 661.50.075 | ||

| 50 | 105 | 120 | 661.50.105 |

Technical Specifications

The accuracy and preservation of the centering precision between the punch and matrix in the molds depend on the quality and wear resistance of the guide pillars / bushing groups. Depending on the developments in the manufacturing industry, Kalıpyansan guide elements offer a long working life with new technology production methods that are constantly updated.