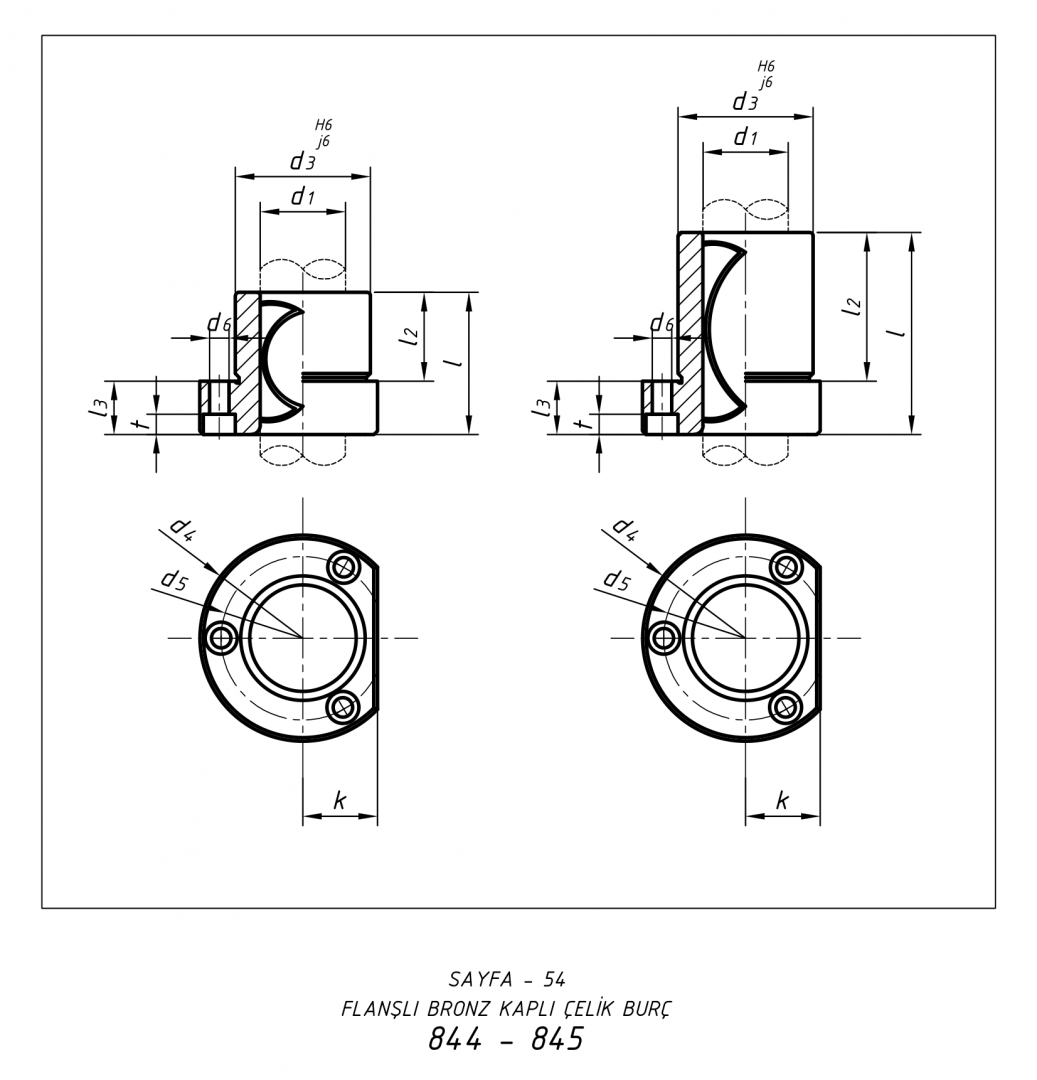

Flanged Bronze Coated Steel Bushes

| MATERIAL | HARDNESS | DEPTH |

|---|---|---|

| Tool Steel / Bronze | 62 ± 2 HRC | 0,5 mm |

| d1 | l | l2 | l3 | d3 | d4 | d5 | d6 | t | k | Order Code |

|---|---|---|---|---|---|---|---|---|---|---|

| 18 | 35 | 21 | 14 | 36 | 52 | 42 | 4,5 | 4,6 | 19 | 844.18 |

| 19 | 35 | 21 | 14 | 36 | 52 | 42 | 4,5 | 4,6 | 19 | 844.19 |

| 20 | 35 | 21 | 14 | 36 | 52 | 42 | 4,5 | 4,6 | 19 | 844.20 |

| 24 | 40 | 25 | 15 | 40 | 63 | 50 | 5,5 | 5,7 | 23 | 844.24 |

| 25 | 40 | 25 | 15 | 40 | 63 | 50 | 5,5 | 5,7 | 23 | 844.25 |

| 30 | 45 | 30 | 15 | 48 | 72 | 58 | 5,5 | 5,7 | 28 | 844.30 |

| 32 | 45 | 30 | 15 | 48 | 72 | 58 | 5,5 | 5,7 | 28 | 844.32 |

| 40 | 55 | 33 | 22 | 58 | 85 | 70 | 6,6 | 6,8 | 33 | 844.40 |

| 42 | 55 | 33 | 22 | 58 | 85 | 70 | 6,6 | 6,8 | 33 | 844.42 |

| 50 | 65 | 35 | 30 | 70 | 104 | 86 | 9 | 9 | 38 | 844.50 |

| 52 | 65 | 35 | 30 | 70 | 104 | 86 | 9 | 9 | 38 | 844.52 |

| 60 | 80 | 50 | 30 | 85 | 120 | 100 | 9 | 9 | 46 | 844.60 |

| 63 | 80 | 50 | 30 | 85 | 120 | 100 | 9 | 9 | 46 | 844.63 |

| d1 | l | l2 | l3 | d3 | d4 | d5 | d6 | t | k | Order Code |

|---|---|---|---|---|---|---|---|---|---|---|

| 18 | 55 | 35 | 20 | 36 | 52 | 42 | 4,5 | 4,6 | 19 | 845.18 |

| 19 | 55 | 35 | 20 | 36 | 52 | 42 | 4,5 | 4,6 | 19 | 845.19 |

| 20 | 55 | 35 | 20 | 36 | 52 | 42 | 4,5 | 4,6 | 19 | 845.20 |

| 24 | 60 | 40 | 20 | 40 | 63 | 50 | 5,5 | 5,7 | 23 | 845.24 |

| 25 | 60 | 40 | 20 | 40 | 63 | 50 | 5,5 | 5,7 | 23 | 845.25 |

| 30 | 70 | 45 | 25 | 48 | 72 | 58 | 5,5 | 57 | 28 | 845.30 |

| 32 | 70 | 45 | 25 | 48 | 72 | 58 | 5,5 | 57 | 28 | 845.32 |

| 40 | 80 | 50 | 30 | 58 | 85 | 70 | 6,6 | 6,8 | 33 | 845.40 |

| 42 | 80 | 50 | 30 | 58 | 85 | 70 | 6,6 | 6,8 | 33 | 845.42 |

| 50 | 90 | 55 | 35 | 70 | 104 | 86 | 9 | 9 | 38 | 845.50 |

| 52 | 90 | 55 | 35 | 70 | 104 | 86 | 9 | 9 | 38 | 845.52 |

| 60 | 100 | 57 | 43 | 85 | 120 | 100 | 9 | 9 | 46 | 845.60 |

| 63 | 120 | 100 | 43 | 85 | 120 | 100 | 9 | 9 | 46 | 845.63 |

Technical Specifications

The accuracy and preservation of the centering precision between the punch and matrix in the molds depend on the quality and wear resistance of the guide pillars / bushing groups. Depending on the developments in the manufacturing industry, Kalıpyansan guide elements offer a long working life with new technology production methods that are constantly updated.