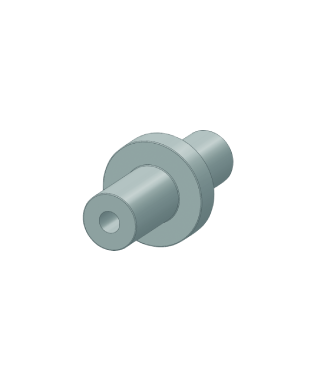

Die Spring Assembling Spacer Bushes

| Die spring hole diameter |

D1 | D2 | D3 | L | L1 | K | Order Code |

|---|---|---|---|---|---|---|---|

| 20 | 19,5 | 10,0 | 4,0 | 36,0 | 15,0 | 6,0 | 750.20 |

| 25 | 24,0 | 12,5 | 5,0 | 46,0 | 20,0 | 6,0 | 750.25 |

| 32 | 29,0 | 16,0 | 8,0 | 60,0 | 25,0 | 10,0 | 750.32 |

| 40 | 38,0 | 20,0 | 10,0 | 70,0 | 30,0 | 10,0 | 750.40 |

| 50 | 48,0 | 25,0 | 12,0 | 80,0 | 35,0 | 10,0 | 750.50 |

Die Springs Selection and Use

Kalıpyansan die springs are capable to meet special requirements of the production in all die and machinery sectors with their 6 different load classes (4 different loads with ISO 10243 Standards and 2 different loads with Kalıpyansan Standards) and engineered for high performance and long service life.

When Selecting Die Springs;

- Select a pressure force demanded available in the measurement table according to the diameters and lengths specified for die springs.

- In case the diameters and lengths are not specified, it must be taken into consideration that the maximum spring pressure is to be provided in the longest spring size when specifying the spring length.

- During selection, it is recommended to take the free length of springs to be exposed to light, medium and heavy load as 6 times of the working distance. For the springs to be exposed to extra heavy load, it is recommended to take the free length as 8 times of the working distance.

- The shorter springs are selected for the cases where the height is not sufficient while the number of spring is increased under control in accordance with the die construction. To allow easy identification die springs are color coded by 6 load classes and offered in a wide range of diameters and lengths.

Technical Specifications

Kalıpyansan die springs are manufactured exclusively from high alloy, chrome silicon quality, rectangular profile spring steel.

- 6 different load classes such as extra light, light, medium, heavy, extra heavy and ultra heavy load are used.

- Each die spring is qualified to meet all requirements with the highest material volume as possible, with the winding inclination of most adequate shape and spiral number. Section size is a resistance preventing flexion of the die spring.

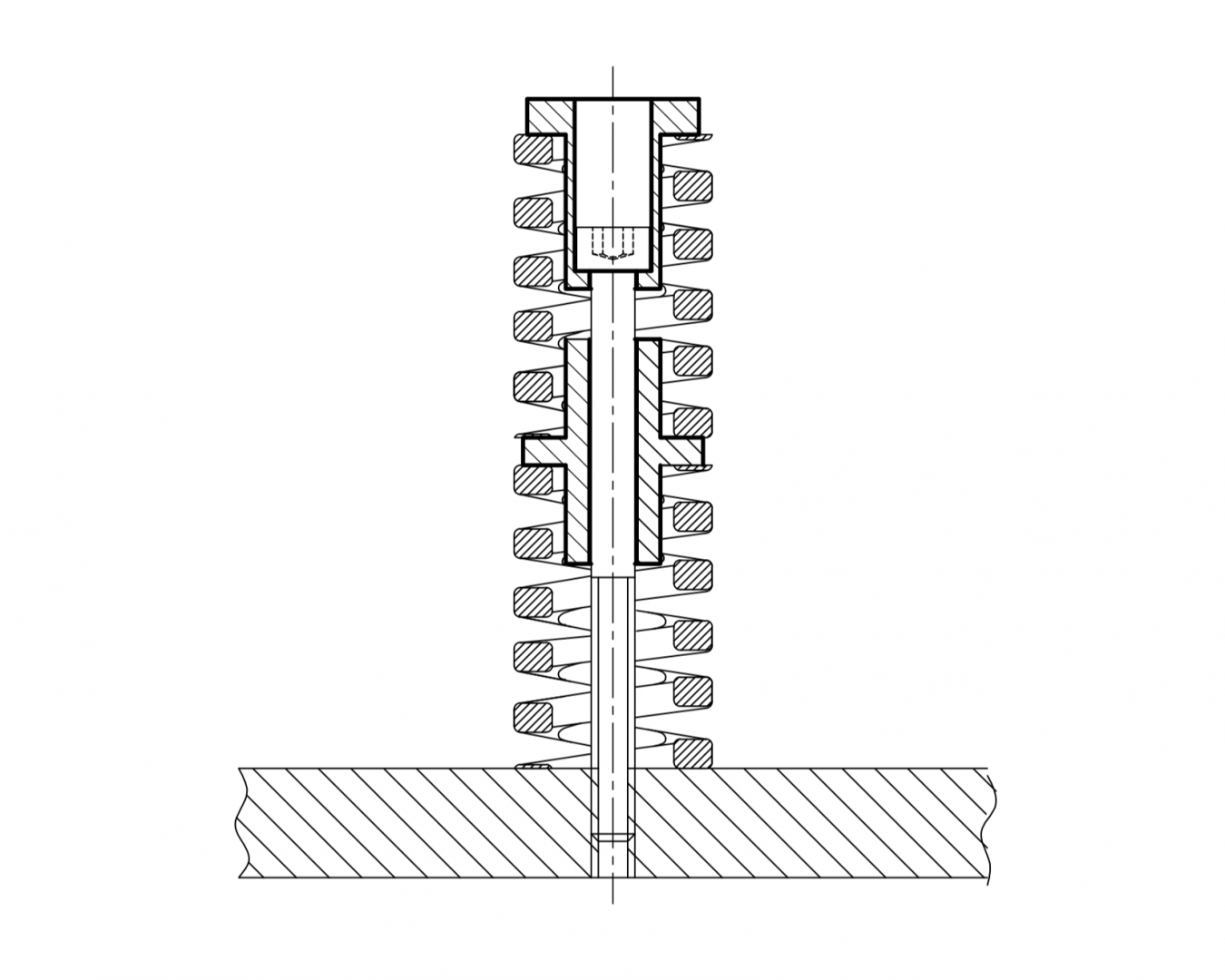

- Attention must be paid to compliance of the holes and arbour diameters. Die springs have been arranged according to 9 different holes and arbour diameters. Spring diameters are guaranteed to fit in the hole and over the rod diameters listed in the dimensional data.

- Ends of each spring are closed and ground square to assure every spring will stand on either end, providing a maximum bearing surface and improving performance.

- Kalıpyansan die springs can be operated at a maximum temperature of 250°C.

- Kalıpyansan die springs do not show any loss of strength up to 120°C. Under conditions where the springs operate above 120°C, an average loss of force of 1% should be calculated at every 50°C increasing.

- When replacing springs, all springs in the same group should be changed together. In order to achieve maximum efficiency, all springs in the same group must be replaced together. The physical properties of the springs should not be changed. (Length cutting, external and internal diameter intervention, etc.)